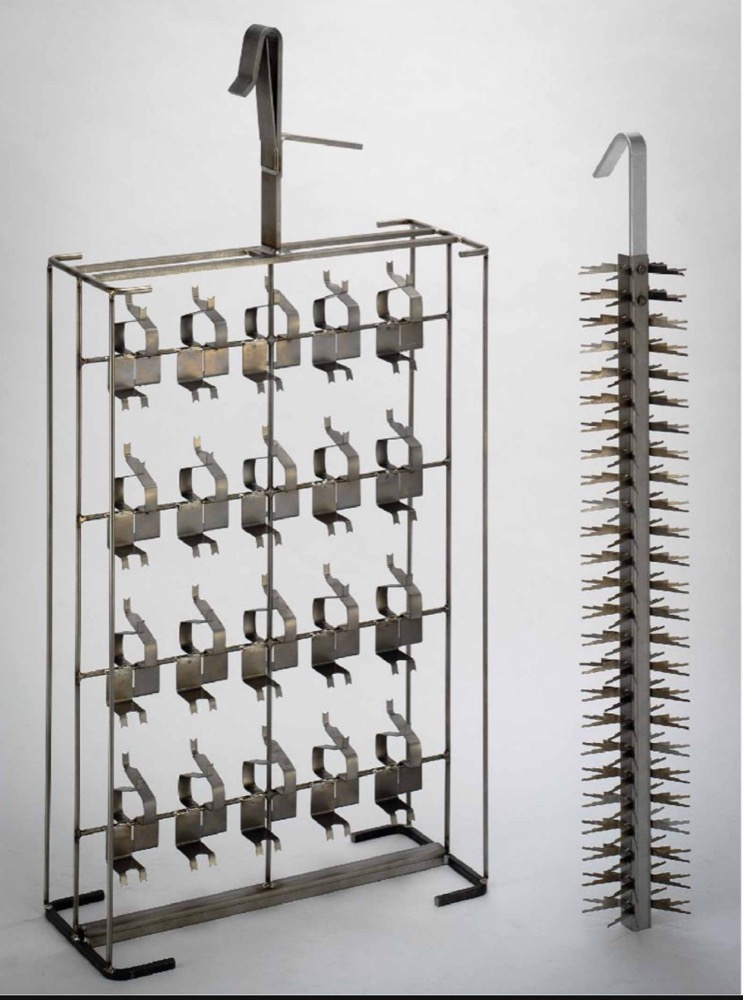

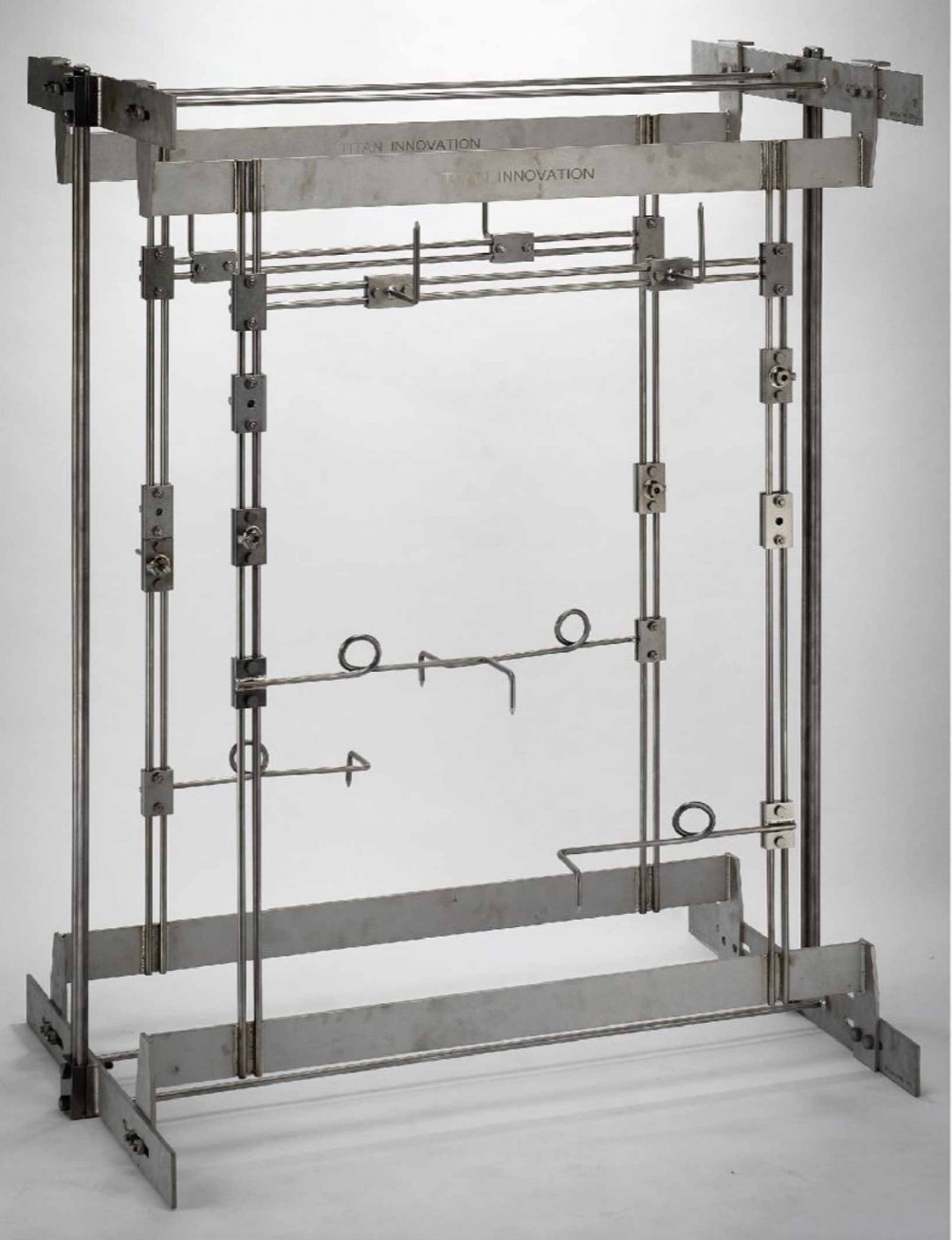

Anodization Treatment Plating Rack

Precise Heater has manufactured and supplied huge volume of Customised Titanium Anodising Jigs to leading Auto components and Aerospace components suppliers across nation.

Why Titanium Jigs:The answers are simple:

1. Aluminum racks are consumable. Anodic film builds up, necessitating stripping.

2. Titanium racks are consistent from run to run.

3. Titanium racks don’t anodize as do aluminum racks. Therefore, you can use your rectifier to anodize parts, not racks.

4. The higher initial cost of titanium racks is more than offset by the in-process savings, better consistency and longer life advantages of titanium.

5. Above all, our titanium racks carry Servi-Sure quality and thought-through engineering into your tanks. The value of having Servi-Sure racks on the job will be realized again and again, in your anodizing.

From our customer service and sales people to engineering, plant operations and shipping personnel, Precise Heater speaks volumes about doing a job the right way, every time, to the customer’s continued satisfaction. That’s why, for your anodizing operation to be its best, talk to Preicise Heater.

Titanium Jigs for Aluminium Anodising and Electroplating

By keeping track of the ongoing market developments, we are engaged in offering an outstanding quality Titanium Jigs for Aluminium Anodising to the customers. The offered products are precisely designed and manufactured in line to industry quality standards by utilizing premium quality raw material and cutting-edge technology under the guidance of skilled and experienced quality controllers. Moreover, we are offering this product in standard as well as in customized form as per the predefined requirement of our prestigious clients at market leading prices.

Key features:

Nationwide coverage by experienced jig and rack engineers to discuss, advise and develop the correct solutions for customers individual requirements

Nationwide collection, refurbishment and delivery service

Dedicated in house design and prototype facilities using the latest technology including 3D CAD, in house laser cutting and latest CNC machining and fabrication technologies

Proven track record that can meet all standard and specialist electroplating and painting requirements

Frame jig, basket and cage designs for plating, spraying and vacuum coating

All types of electroplating jigs and racks

PVC, Nylon or Halar coat

Titanium anodising jigs bespoke to suit individual customer requirements as well as Preciseheater’s standard titan range.

Baskets of all types including standard or dedicated work handling

Nationwide collection and repair service

Suppliers to aerospace and automotive Tier 1